Ready to create experiences?

Message from the Managing Director

Thank you for visiting our website and discovering more about Archmill House and our custom millwork services.

Archmill House team has seen tremendous growth in both sales and staff. Today, we have over 180 employees and have developed strong partnerships with industry-leading clients in both Canada and the United States. I am thrilled to see that Archmill House is changing the way millwork companies do business in our industry.

Our commitment to building a strong culture within our organization and a focus on investing in our staff through training and education is playing a crucial role in driving this growth and prosperity.

Our commitment to “flawless execution” within our leadership and operations team ensures the continued growth and financial health of Archmill House.

The future looks bright for the Archmill House team and its partners.

OUR VALUES

AGILE| COLLABORATIVE| COMMITMENT| INTEGRITY

Mission

Our commitment is to provide quality architectural products on time and on budget to the environments of our clients, where our personnel are challenged and inspired to reach their full potential and make a difference.

Our Vision

To be number one in Architectural Interiors for multi-location enterprises.

Purpose

Providing solutions for Architectural Aspirations in the workplace.

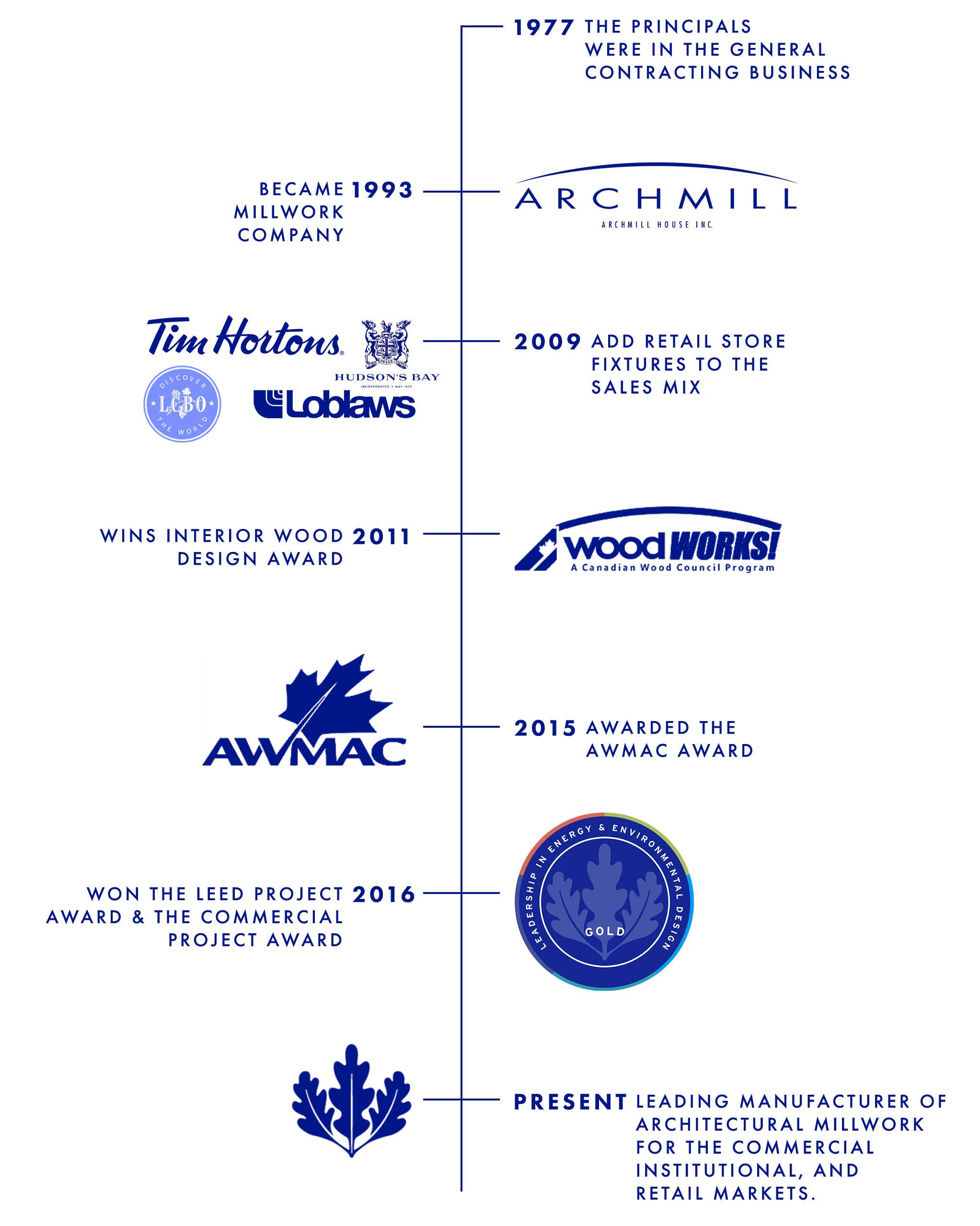

Family Owned & Operated Corporation

Established in 1993, Archmill House is a closely-held, family-owned and family-operated company based in Ancaster near Toronto, Ontario, Canada. Our focus is on the manufacturing of architectural millwork, case goods and store fixtures for the Commercial, Institutional, and Retail markets.

Over the years we have invested heavily in state-of-the-art equipment and facilities to seamlessly manufacture, deliver, install and service our own product.

Commitment to Quality & Customer Service

However, more important than equipment is our commitment to quality and customer service. In addition to being a qualified member of AWMAC and the Gold Seal Program, Archmill applies Lean Principles, Kaizen, and 5S continuous improvement processes and Quality Assurance standards. We are also committed to sustainable design and to date we are a participant in 18 LEED certifications.

All of our full-time staff are required to take ownership of their work, job or service. Every client is assigned an Archmill team that will oversee the total cycle from original shop drawings, through manufacturing and assembly, to delivery and installation. We believe that quality begins and ends with each employee!

For over 20 years, Archmill has been driven to be the best in the custom millwork industry. We will continue this tradition by combining strong management, effective administration, technical knowledge and expertise, and highly skilled tradespeople that take pride in creating a quality product.